The past few years have marked the automotive industry with several radical changes and transformations. Now the innovation that should be introduced would be one driven by artificial intelligence. Stellantis is at the forefront of this revolution that will surely go down in history, implementing different solutions to greatly increase the production efficiency of companies. Another key aspect would be the reduction of environmental impact, also improving the working conditions of employees.

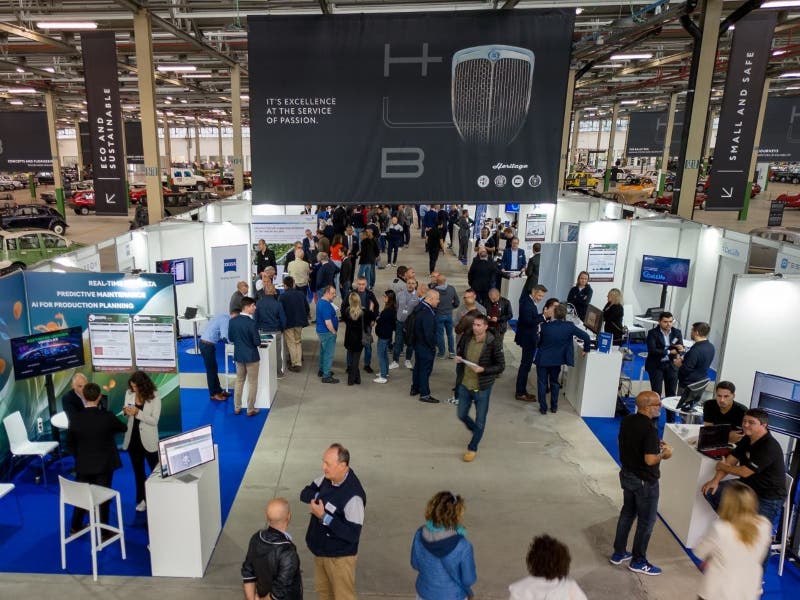

Stellantis featured at Factory Booster Day

The Stellantis Group is slowly revolutionizing more and more the way cars are produced, putting important issues such as innovation and sustainability at the forefront. At the center of this change is Factory Booster Day, an event held annually. It is a celebration in which suppliers and startups collaborate to try to identify solutions that are absolutely cutting edge, useful for improving factory efficiency. So we can say that increasing production efficiency, sustainability, and improving jobs within facilities are the key factors for the Stellantis Group to implement all these innovations that are based on artificial intelligence.

The 2024 Factory Booster Day edition saw the presentation of as many as 93 new solutions, which are the result of a continuous and exhausting quest to optimize production processes. It would aim to reduce costs as much as possible, while minimizing environmental impact and consequently ensuring the highest quality of the final product. However, the current results are already quite evident. In fact, since 2021, Stellantis has recorded a reduction in labor costs that is about 11 percent, as well as a 23 percent drop in energy consumption and a 40 percent drop in problems concerning quality.

Artificial intelligence at the service of automotive manufacturing

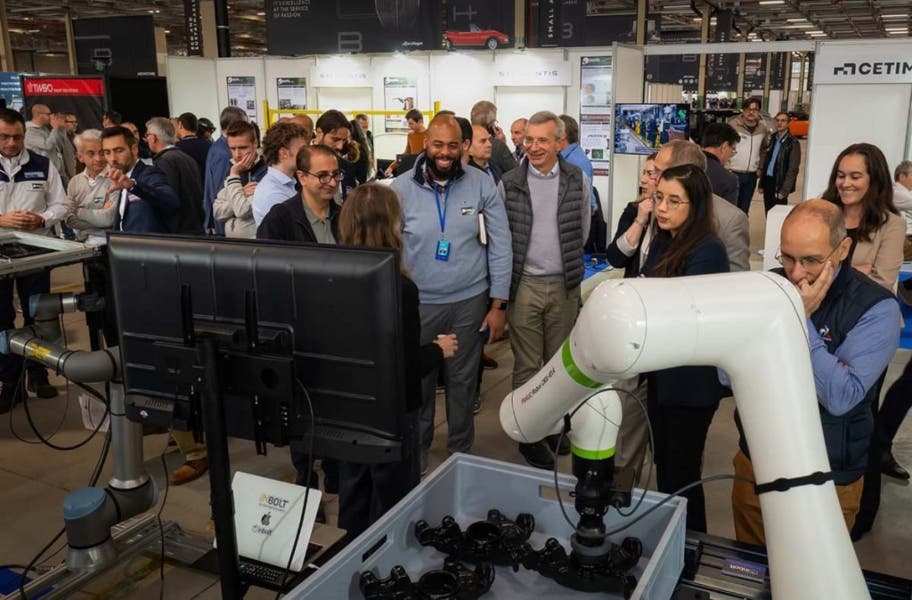

This valuable transformation includes artificial intelligence (AI) as a major player. 3D vision systems, autonomous robots and cloud platforms have been completed that offer the great opportunity for companies to automate processes as much as possible, greatly improving accuracy, while also optimizing the management of materials used. A very relevant instance of this innovation is the use of Autodesk Construction Cloud, which is a platform that enables the creation of a “digital twin” of factories. This, allows to greatly facilitate and simplify the planning and management of company projects, or of the facility itself.

The Autodesk Construction Cloud implementation, initiated with the installation of STLA Large at the Windsor plant, has proven the effectiveness of this solution in accelerating processes and reducing costs. Their success has led to the expansion of the project to Sterling Heights, where STLA Frame is currently being installed. This integrated and collaborative approach is transforming the way Stellantis designs and builds its vehicles.

The collaboration with other entities that can improve Stellantis’ strategy, is a very important factor within the group’s strategy. The company very actively involves both its suppliers and startups, creating an innovation ecosystem that allows them to work consensually to arrive at the development of increasingly advanced solutions. All this, always keeping the focus on the sustainability factor, without which it is not possible to proceed. Stellantis, plans in its business strategy to become a carbon neutral company, by the year 2038. Now, production that is affected by additional innovation systems plays a key role in achieving this business goal.

Benefits of Stellantis’ innovations

The advanced innovations that were presented by Stellantis at the event are different and all important. Increased efficiency, which lies in process automation, which would reduce production time and optimization of available resources. The idea proposed by Stellantis, also involves better process control, substantially reducing errors. It would also result in rapid adaptation to market changes, reducing environmental impact and optimizing energy consumption.

Stellantis – as we well know – wants to prove that technological innovation combined with the auto industry sector, can achieve great results. It is continuously working with external partners to collaboratively arrive at a satisfactory result in the very near future. Recall, reaching the ambitious goal of becoming a net-zero company by 2038, part of its ‘Dare Forward 2030‘ Stellantis is investing in industrial innovations that reduce the environmental impact of its products and processes. And precisely, also thanks to these advanced technologies such as automation and artificial intelligence, the company is trying to improve quality while decreasing costs, thus optimizing production. All, of course, while respecting the environment.