This initiative implemented in vehicles produced at the Goiana Automotive Complex will reduce more than 2,100 tons of CO2 emitted during fuel combustion during the first refueling, representing a reduction of about 87 percent in emissions. As of today, vehicles with T270 Flex and Turbo 270 Flex engines produced in Pernambuco will leave the factory fueled by ethanol. In 2025, the initiative will be extended to the automotive hubs of Minas Gerais and Rio de Janeiro.

First Stellantis ethanol refueling in Gioana

The Goiana plant of the Stellantis Group is experiencing in these hours one of the events that will surely go down in history. With the important presence of the Vice President of the Brazilian Republic, Geraldo Alckmin, along with an institutional delegation, the automotive group has carried out the first refueling of 100 percent ethanol for Flex vehicles in the range that are produced by the company.

This was a truly epic moment, both with regard to the transition to zero-emission mobility, but also for Brazil’s auto sector. Indeed, in this country, Stellantis is now projected to be at the top of sustainability for this sector. Thus, starting now, models that are already well known in the world market, such as the Jeep Renegade, Compass and Commander, will be rolled off the production line already powered by ethanol. In addition, the Fiat Toro will also be favored in this new beginning, and during the course of next year, this innovation will involve all the company’s automobile hubs throughout Brazil.

Benefits from the ethanol revolution

So what would be the real concrete benefits of this new revolution in the automotive sector? For starters, the first positive factor certainly concerns the most important issue, namely a decidedly different environmental impact. For studies carried out in this regard have estimated that with this first refueling in Brazil, it will be possible to reduce more than 2,100 tons of CO2. We are talking about a very important figure, which in percentage terms would amount to about 87 percent less, if we refer to the use of the fuels that are still normally used today. A very good result indeed, which highlights the tenacity of Stellantis in continuing in this difficult struggle.

South American feedstocks for ethanol supply

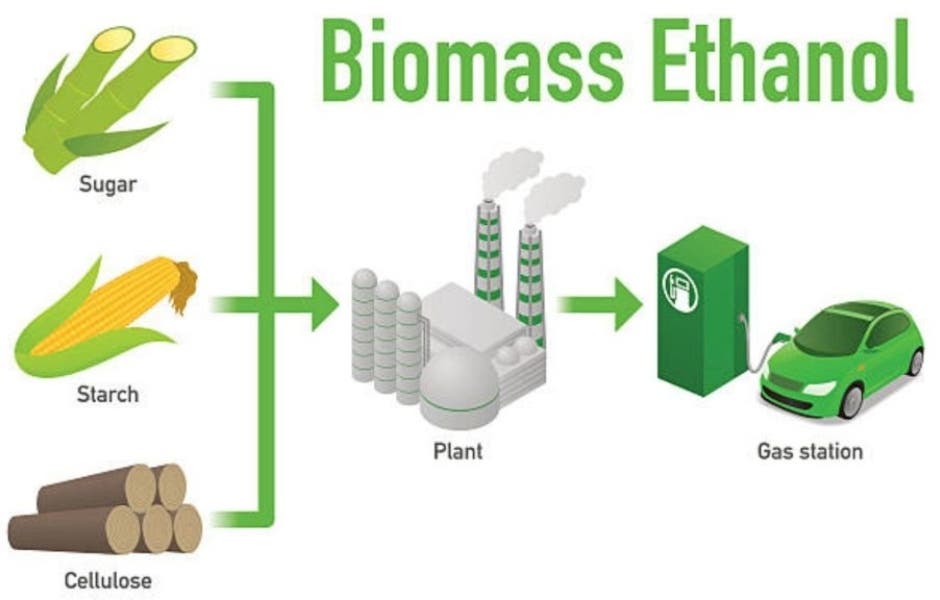

Choosing to have made a first refueling in Brazil, of course, is not accidental on the part of Stellantis. The South American country, in fact, has a rich production of sugarcane, which has contributed substantially to the production of this important biofuel for centuries. Ethanol, of course, offers numerous advantages, among which we see mainly sustainability. In this respect, sugarcane absorbs large amounts of CO2 as it grows, so it perfectly offsets the emissions produced by burning the fuel we use every day. Another positive aspect of ethanol is its flexibility, as the technology being used for flex-fuel cars allows the vehicles to run perfectly on both gasoline and ethanol. This gives consumers more freedom of choice. To top it off, if ethanol is used, it contributes greatly to the creation of a circular economy, which helps reduce the heavy reliance on fossil fuels.

Decarbonization by the year 2038

As already known, Stellantis was founded with a strongly futuristic vision that included sustainable mobility from the very beginning. In fact, the company’s plan remains to decarbonize the entire production cycle of its cars and plants by the year 2038, with an initial major 50% reduction as early as 2030. For this very reason, the company is constantly striving to seek out and propose solutions and strategies to the automotive industry that always address low carbon emissions. Emanuele Cappellano, president of Stellantis for all of South America, also spoke in this regard. He explained that by powering vehicles at the factory exclusively using ethanol, the company helps neutralize greenhouse gas emissions. But of course, Stellantis’ big goal does not stop only at vehicle production. Rather, the actual goal, in fact, concerns the positive impact that affects the entire life cycle of each individual car, starting from raw materials and ending with disposal.

Reference solutions promoting sustainable mobility

This Stellantis initiative most certainly provides a benchmark and an example for all vehicle manufacturers. Thus, particularly, Brazil confirms its vanguard when it comes to the unbridled search for solutions that are suitable for sustainable mobility. In this field then, the importance of ethanol is truly invaluable, presenting itself as a viable alternative, concrete and competitive, to reduce emissions as much as possible and fight climate change with good weapons.

The adventure that has just begun involving ethanol has all the characteristics to prove the revolutionize the way we move every single day. By this initiative, the Stellantis Automotive Group confirms its continued commitment to an emission-free future, just as at the same time Brazil strengthens its global leadership as a producer of biofuels.