Stellantis has patented a new technology that improves drainage and replacement of automatic transmission lubricant at the United States Patent and Trademark Office (USPTO). The patent, officially issued on January 28, 2025, relates to a new system that uses an electrically powered auxiliary oil pump to improve drainage that traditionally relies on gravity. This ensures a more accurate drainage procedure and eliminates the need to run the engine during maintenance activities.

Stellantis patents new technology that improves automatic transmission fluid drainage

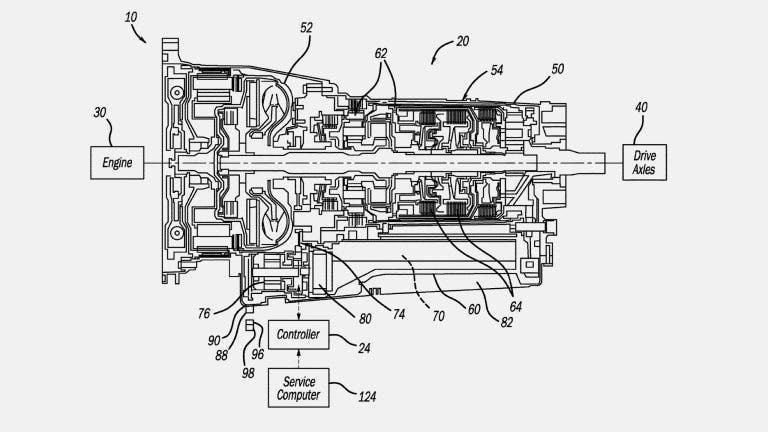

The new system proposed by Stellantis is incorporated into the automatic transmission. The latter includes a torque converter, transmission, and an electrohydraulic control system. A transmission control module manages gear shifts by directing transmission fluid to improve clutch engagement or disengagement. It is known that transmission fluid plays a fundamental role in lubricating internal components and maintaining proper hydraulic pressure. The transmission system includes both a mechanically driven oil pump and an auxiliary oil pump powered by a dedicated electric motor. This auxiliary pump allows fluid circulation even when the engine is off, offering greater flexibility during necessary maintenance operations.

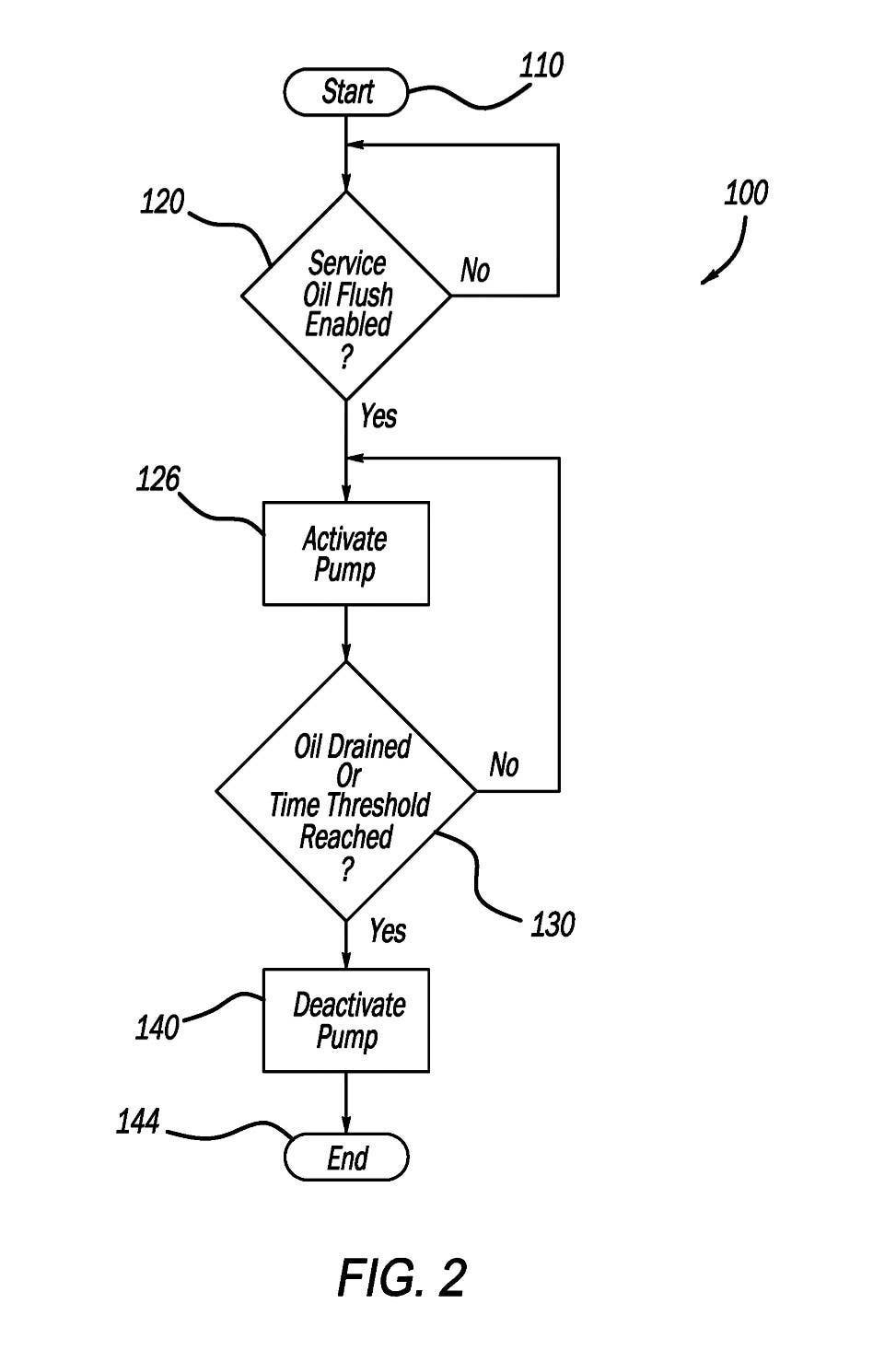

The patent filed by Stellantis with the United States Patent and Trademark Office requires that certain fundamental steps be followed during maintenance activities. First, a service technician uses dedicated service hardware to enable an oil replacement or flushing service. Then the drain plug is removed, leaving the drain hole free. The transmission control module then commands the auxiliary oil pump to activate, circulate and expel the transmission fluid to be replaced through the drain hole. The system determines when the fluid has been sufficiently drained using multiple evaluation methods, including:

- Monitoring a hydraulic solenoid that detects variations in fluid flow;

- Monitoring pump running time against a preset time threshold;

- Measuring the volume of drained fluid;

- Observing variations in pump load as fluid reduces increases efficiency;

- Technician verification of minimal fluid leakage from the drain hole.

Once emptying is completed, the auxiliary pump is deactivated, ensuring an optimized and efficient fluid replacement process.

According to Stellantis, this recently patented technology allows several advantages to be developed. Among the main advantages is certainly the fact that this new methodology allows for a more complete transmission fluid replacement compared to traditional methods based only on gravity. At the same time, it actively eliminates any debris reducing contamination risks, also improving safety since the process execution does not require engine startup. Efficiency then increases by reducing labor times and dependence on external equipment, so it can also be adapted to other hydraulic systems, besides just automatic transmissions.

With this new patent, Stellantis strengthens its commitment to innovation also in the maintenance of its vehicles, offering a non-intrusive and highly efficient approach to automatic transmission maintenance. This progress optimizes vehicle performance while simplifying maintenance procedures.